# Basics

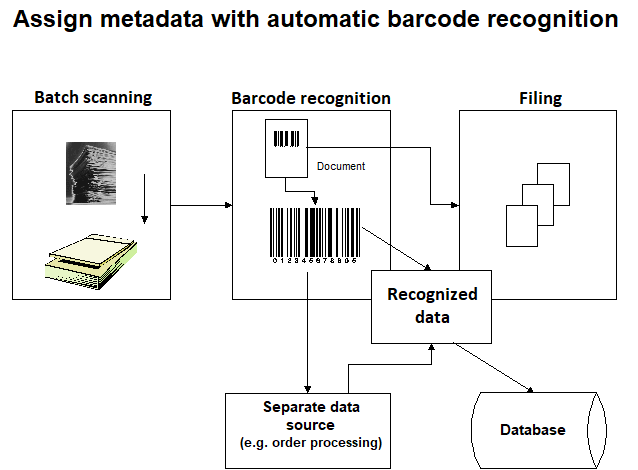

Barcodes are used to encode characters and numerals. This enables you to uniquely assign information that the ELO Barcode module can read quickly and reliably, and then use this information to index documents.

One important aspect in filing documents electronically is assigning them the correct metadata so that you can access the document without any problems at a later point in time. Errors in manual entry, such as entering incorrect customer or invoice numbers, result in unsuccessful searches. ELO Barcode simplifies and speeds up metadata entry and indexing processes.

# Overview of functions

The main functions of ELO Barcode include:

- Automatic barcode recognition for scanned documents

- Converting barcodes into search terms (indexing)

The barcode is read during filing from the Intray to ELO. The following options are available:

- Defining a rectangular area in which the barcode is located (barcode area)

- Searching an entire document

You can assign parts of the barcodes to different fields in the metadata form. You can also define the characters of the barcode as a verification feature. During barcode conversion, ELO turns this barcode content into searchable attributes (metadata).

# Factors that affect barcode recognition

# Quality

Scanners are grid-oriented devices that usually work with 200 to 400 dpi (dots per inch). If a grid-oriented device scans a symbol without a grid, valuable information is lost. There are many other factors resulting in additional loss of data or even in data distortion. Poor recognition results can only be avoided if all the factors are considered to the fullest extent. The following factors must be taken into account to guarantee reliable barcode recognition:

- Barcode type

- Resolution (dpi)

- Barcode width

- Vertical barcode height

- Barcode symbol alignment

- Quiet zones

- Scanner settings

- Document quality

- Barcode label quality

# Barcode recognition characteristics

Barcode recognition is primarily used to assign documents metadata. You can automate this process to prevent any errors from occurring. System performance and data integrity depend on the reliability of the device for barcode recognition as well as on the image quality. ELO Barcode uses the best possible scanning algorithms. However, this alone does not automatically ensure a high rate of recognition. The preceding list therefore explains the individual factors that will help you achieve reliable barcode recognition.

Information

Distorted or damaged barcodes can cause errors in barcode recognition.

# Barcode type

The structure and design of a barcode symbol frequently lead to poor readability. Barcode type Code 39 seems to have the highest tolerance with a marginal corruption of the input data. This is why we recommend using Code 39.

# Resolution in dots per inch (DPI)

Barcodes can be scanned reliably at a resolution of 200, 300, and 400 dpi. Lower dpi values require larger barcode symbols to achieve reliable recognition. For good results, we recommend you select the character density of the barcode symbols according to the values listed below.

# Recommended barcode width

The width of the barcode is one of the most important factors for reliable barcode recognition. The wider the barcode is, the better the symbol resolution and recognition.

There is no formula to determine the best width for a barcode symbol. The general rule is not to exceed the following values:

- 6 characters per inch (one inch = 2.54 cm) at a resolution of 300 dpi

- 4 characters per inch (one inch = 2.54 cm) at a resolution of 200 dpi

These values include all the characters of a barcode symbol, such as synchronizing, data, start, and stop characters as well as the optional check digit.

# Vertical barcode height

Theoretically, ELO Barcode is capable of recognizing a barcode that is only one scan line high. However, in reality the barcode symbols have different alignments, i.e., the barcode does not run parallel to the vertical and horizontal margins of a document. This is caused, for example, when barcode labels are applied manually, when the printer is not aligned correctly, or when the scanner is not aligned properly. Under normal circumstances, ELO Barcode reads the barcode from left to right.

The highest degree of reliability is achieved when the barcode is placed such that one horizontal scan line comprises the entire barcode symbol from start to stop character. To recognize the left and right margins of the symbol in a single line, the barcode's vertical size needs to be large enough to allow for a maximum angle ("angular position").

# Barcode symbol alignment

If a barcode is placed on the document at an angle, this could cause a single scan line to miss information (from start to stop character) of a barcode. ELO Barcode offers an alignment correction option for reading barcode symbols placed at an angle. The alignment correction function helps recover information from barcodes place at an angle. However, using the correction feature has a definite impact on scanning speed. It can also cause scan errors. This is why we recommend only using the function as a backup and not in normal operation.

# Quiet zones

Most barcode standards require a "quiet zone" to the left and right of the barcode symbol. In a bitmap image, this quiet zone should be entirely white. Noise ("dirty" pixels in the image) or text "shimmering through" and label edges often result in corrupted quiet zones. This can cause errors in barcode recognition.

A quiet zone at the top or bottom of a barcode symbol must have a height of greater than three pixels. The quiet zones to the left and right of the barcode symbol must be a minimum of eight pixels wide.

# Scanner settings

Many scanners feature a contrast setting option. This threshold-value setting determines the shade of gray when a pixel is no longer interpreted as white but as gray or black. This option allows you to adjust the scanner to the individual properties of the respective documents.

Changing the threshold value could cause the black areas in the barcode symbols to appear wider or narrower than they really are. This process is also called "distortion". The barcode symbols may become illegible even if they look perfectly acceptable to the human eye.

# Barcode quality

Keep the following in mind when placing barcode labels:

- The width of the labels should allow for quite zones around the barcode.

- The barcode resolution and display should be sufficiently dimensioned.

- The printing resolution should be 300 dpi or higher.

- Labels printed with matrix printers are not permitted.

- Label printers with ink ribbons are problematic.

- The glue must be of high enough quality to prevent the labels from rolling up or peeling off.

- The label paper must be thick enough to avoid "shimmering through" of text that is covered by the label.

# Enable barcode recognition

Requirement

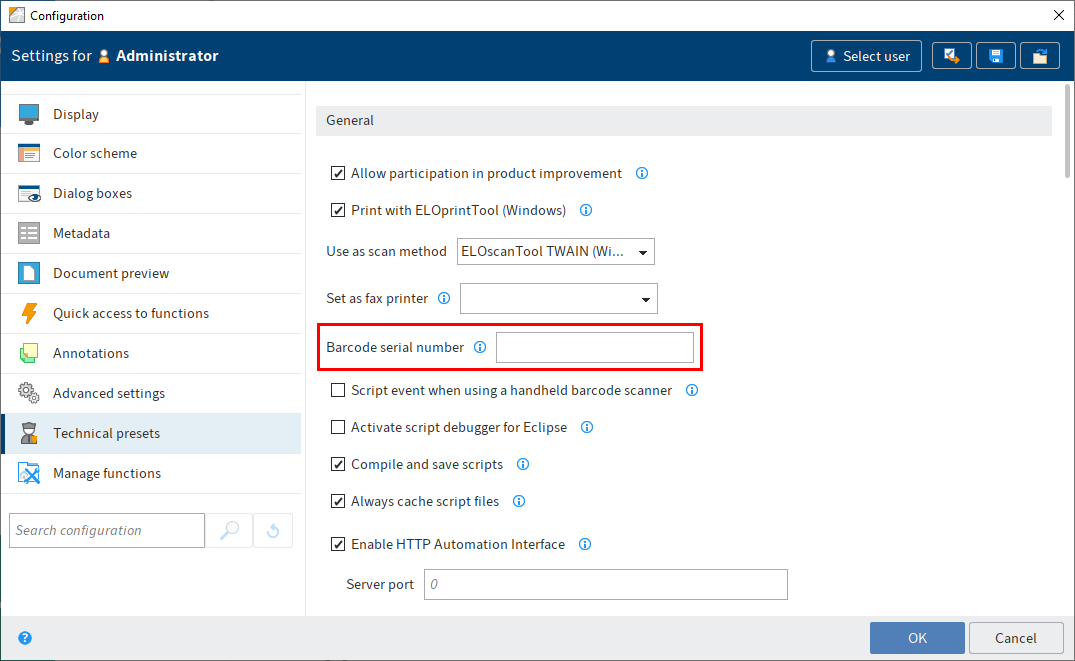

ELO Barcode is automatically installed along with the ELO Java Client. To activate the module, you need an ELO Barcode serial number.

Please note

Barcode serial numbers are unique to each workstation and may not be used multiple times.

Information

The input field for the ELO Barcode serial number is only visible to administrators.

Method

Open the ELO Java Client.

Press F12 to open the configuration.

Enter the ELO Barcode serial number in the Technical presets area.

Select OK to save your entry.

Result

Barcode recognition is activated.